|

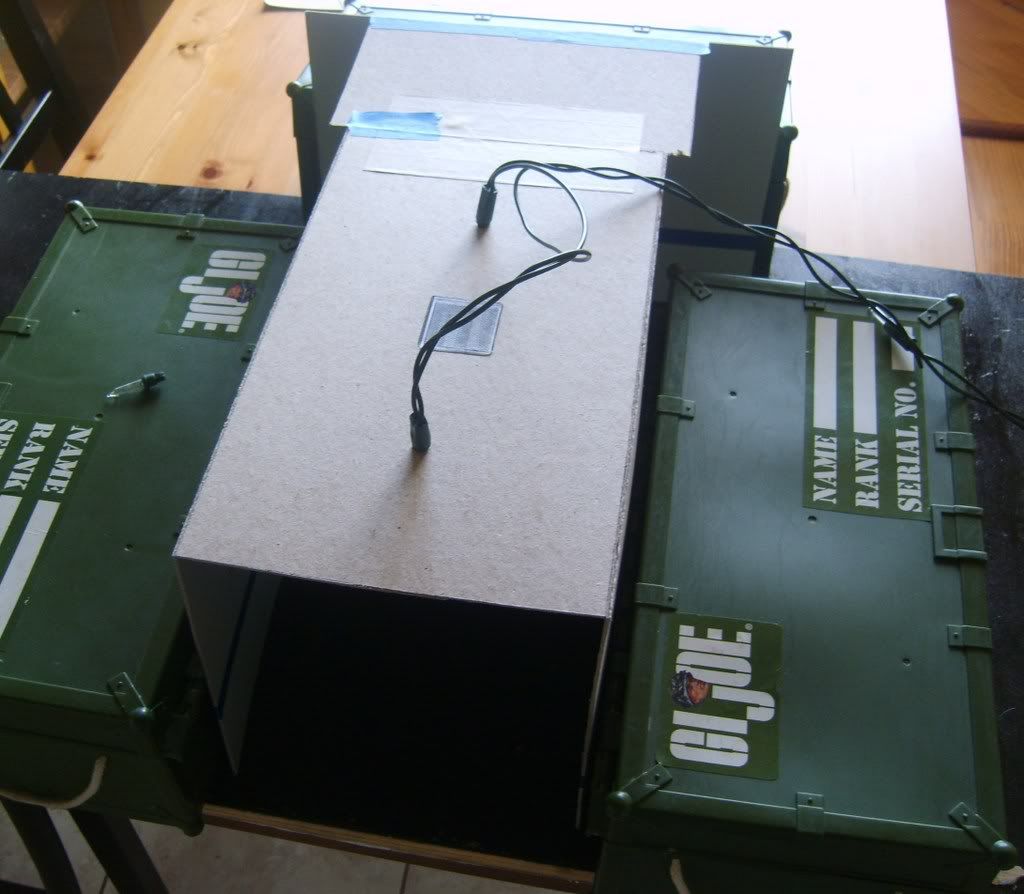

Hallway Set.

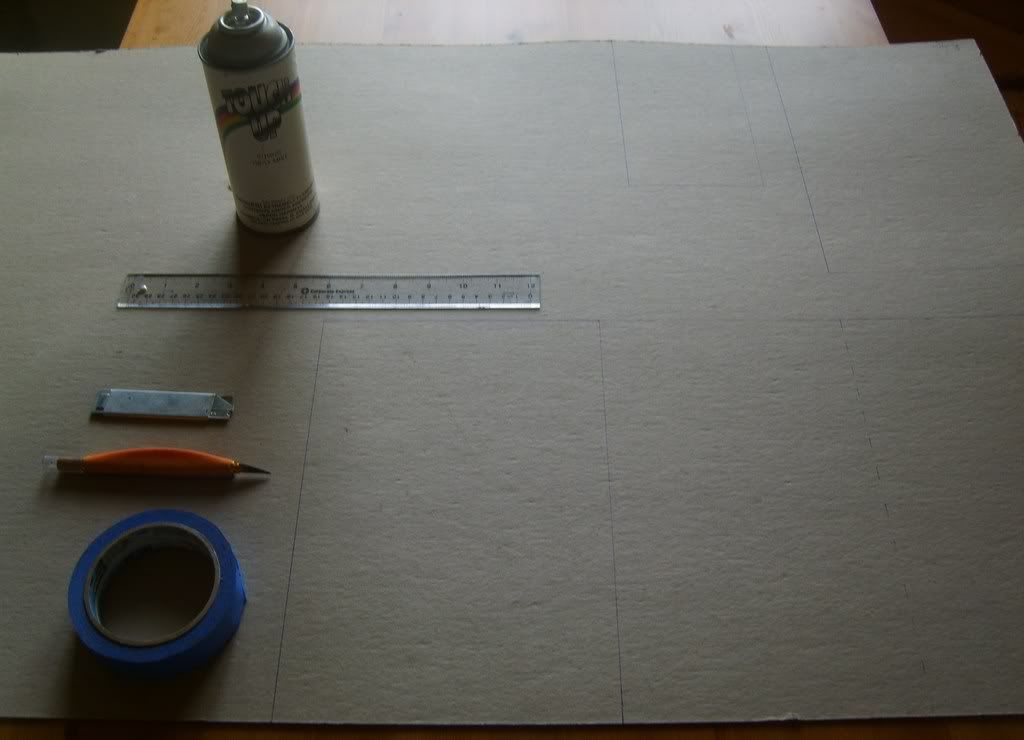

THIS IS MY FIRST ATTEMPT TO EXPLAIN A HOW TO SO BARE WITH ME. FIRST IS A LIST OF MATERIALS YOU'LL NEED

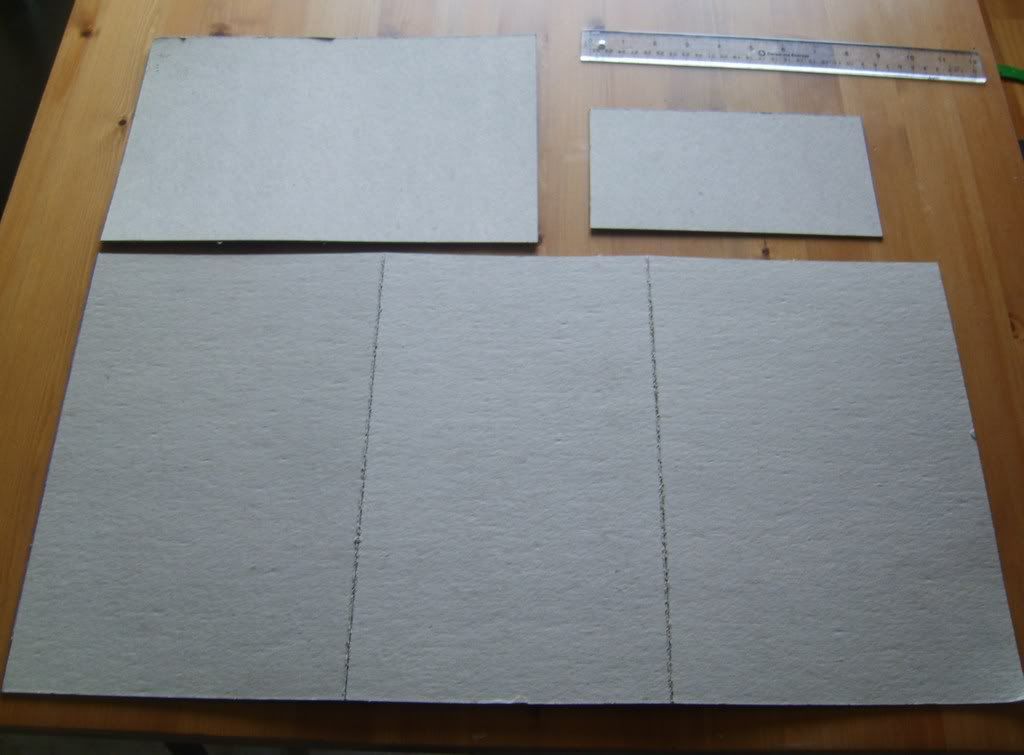

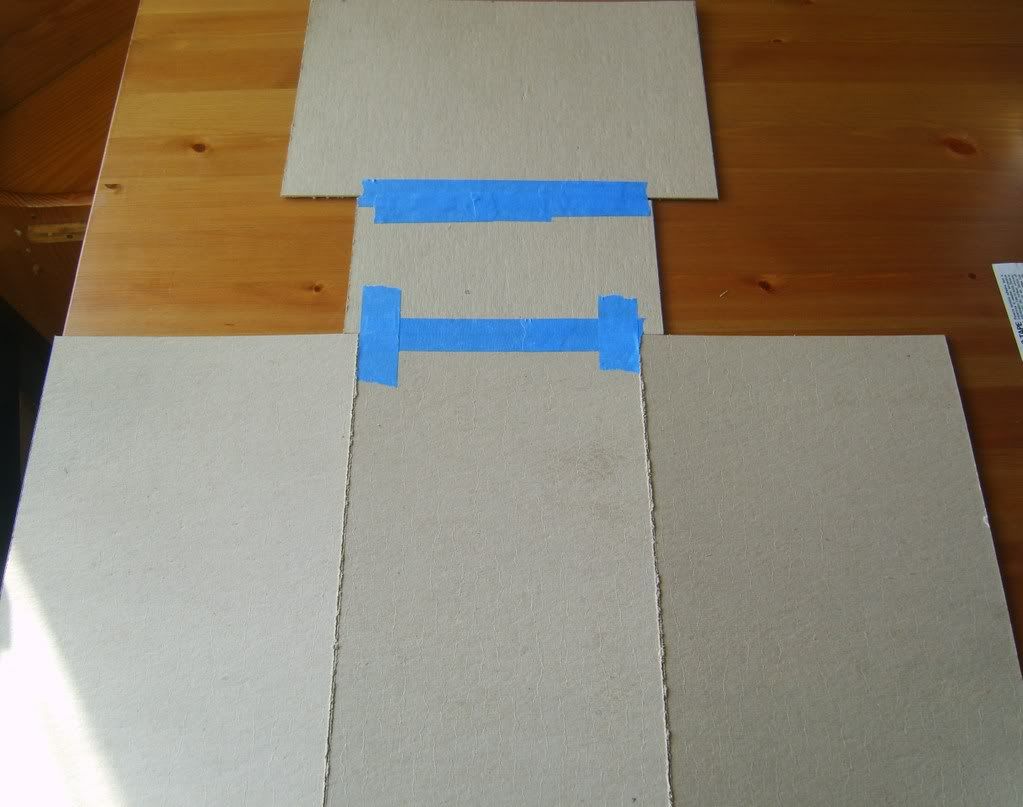

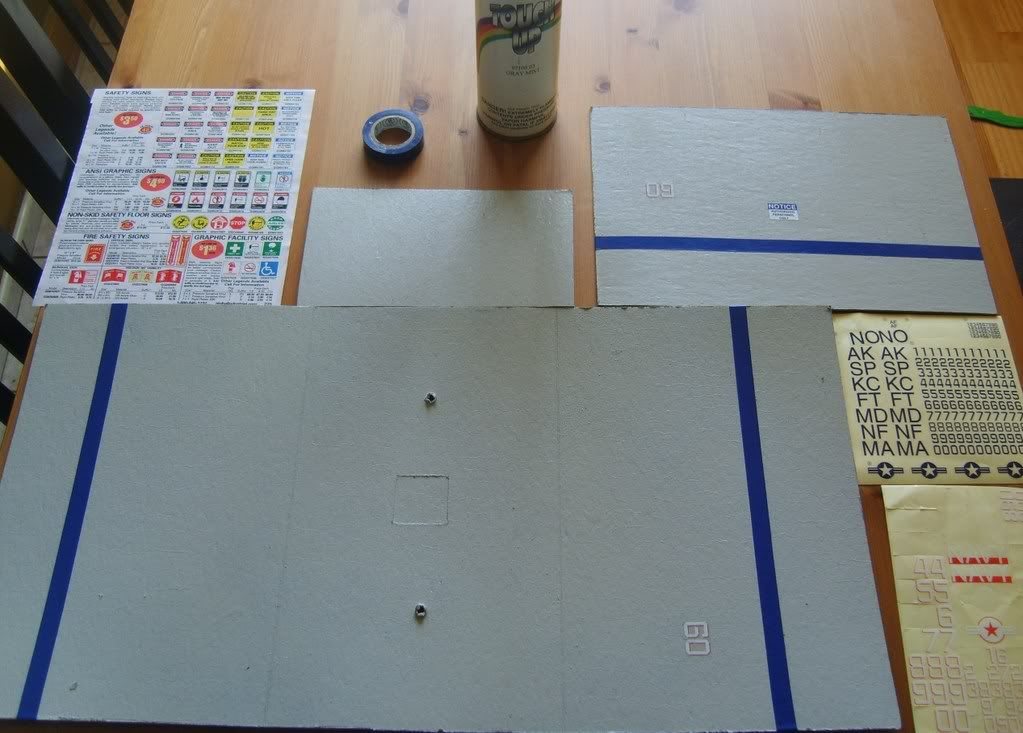

TO BEGIN MEASURE OUT YOUR HALLWAY. THESE ARE THE MEASURMENTS I USED WALLS 12X8, CEILING 12X7, HALLWAY CEILING 8X4. INSTEAD OF CUTTING 3 PIECES CUT ONE BIG RECTANGLE. THEN SCORE THE CEILING PIECES. THIS WILL MAKE IT EASY TO FOLD.THEN CUT OUT ANOTHER WALL PIECE.  ONE PROBLEM I HAD WAS PROPING UP THE BACK WALL SO I USED TAPE FOR THE BACK CEILING  THE LAST AND MOST FUN IS PAINTING AND ADDING DETAILS I USED MAGAZINE SIGNS THAT I CUT OUT AND GLUED. I PUT SOME LIL HOLES FOR LIGHTS AND ADDED A VENT THAT POPS OPEN  SINCE THE WALLS ARE COLAPSABLE IT STORES EASILY. JUST USE HEAVY OBJECTS TO HOLD UP THE WALLS.  IT'S ALSO HANDY THAT YOU COULD LIFT EITHER SIDE OF THE WALLS FOR DIFFERNT ANGLES AND THERE YOU HAVE IT A HALLWAY SET  |

man, that is smurfing sweet. i mean how simple did you make that look. even i think i can do it, maybe not, but i think i can, i think i can.

|

Awesome!! One of the best How-To's I've seen in a LONG time!!

|

I was trained by Luke Ellison so I rely on foamboard myself. But I also built on his original hallway/corridor building. If you want the walls to sit up easily, you can use L-brackets bought from Lowes or Home Depot. I have a bunch of extras since taking apart my sets. Mind you, you use those, you might as well use a wood base so the setting won't warp or buckle.

I admit, the one thing that foamboard does NOT do is show texture. A friend at work who plays around with doing these sort of things too (she's an anime freak), she uses spackle to cover the walls to give them texture then paints over them. It supposedly keeps the foamboard from warping. *shrug* But I like your use of cardstock! I could've sworn I did a how-to of how I do things, but it seems to have disappeared from my blog... Anyway... Very good. |

BTW, I suggest using a metal ruler. The metal won't chip or slice apart when cutting like a plastic one will. This will, in theory, help you keep straight edges when cut. That's in theory cuz the next step is creating proper 90 degree angles cuz there's nothing worse than a wall that ends up being 7" at one end and 8" at the next!

|

Quote:

This sounds interesting...have her log on and give us some pointers......I'd love to see how she does it different! |

Quote:

I'm with ender098...new perspective is always welcome. |

BTW...I'm very impressed with your construction. Cardstock, while light is notorious for misshaping and warping. Foam core is stronger but also has its own set of problems as Sonnelion pointed out.

|

Quote:

I USED WHAT I HAD AVAILABLE. WE HAVE A BUNCH OF THAT STUFF AT WORK :p |

The reason I used foamboard was that it'll last longer and won't damage as easily. Yes, when painted, it warps. But I learned to crack the other side to straight the walls out. You NEVER notice in my dios that the walls were originally warped.

Now, I suppose I could tape cardstock ON foamboard and go from there. Mind you, I had 2 boxes full of foamboard walls so I could use them over and over. That's also the reason why I used thick wood for the base and L-brackets. I can remove the walls, but I'll have the base that I can take anywhere and change the walls up as much as I want. Taller, shorter and at times, longer or shorter corridors. |

Thanks for sharing your cool tips Flatline. Time to get to work! ;)

|

VERY well done Flatline!!!

You remind me that I really should post up some of the 'How-To's' that Flint and I employ........... |

If I get a few days off I might give this a try.

|

This is great. I need to make some hallways to finish a Story I started a few months ago. That will make it alot easier.

|

| All times are GMT -7. The time now is 07:46 AM. |

Powered by: vBulletin Version 3.0.6

Copyright ©2000 - 2024, Jelsoft Enterprises Ltd.